In the world of manufacturing, blow molding is a widely used process for creating plastic products. This technique has seen incredible advancements throughout the years, and now we have the efficient Extrusion Blow Molding Machine.

What is Blow Molding?

Blow molding is a manufacturing process used to create hollow plastic parts by blowing air into heated plastic material that is placed in a mold. Once the plastic material is heated and formed, it is then inflated with air to create a hollow space. This process is used in creating containers, bottles, toys, and other objects made from plastic.

Blow molding has two different types: injection blow molding and extrusion blow molding. Today, we'll talk about extrusion blow molding and how it is made possible with the Extrusion Blow Molding Machine.

What is Extrusion Blow Molding?

Extrusion blow molding is a process used to create a variety of plastic products. One of the most significant advantages of this method is that it can produce large quantities of items quickly and efficiently.

Extrusion blow molding begins with plastic pellets being fed into a hopper at the top of the machine. These pellets are then fed through a heating chamber, melting the plastic. Once melted, the plastic is extruded through a die head to form a parison - this is a hollow tube like an inflated balloon.

The parison is then transferred to a mold and pinched together on each end. A blowing pin is then inserted into the parison, and air is blown into the plastic, causing it to expand and fill the mold. Once the plastic has cooled and formed, the mold is opened, and the finished product is then ejected.

Extrusion Blow Molding Machine

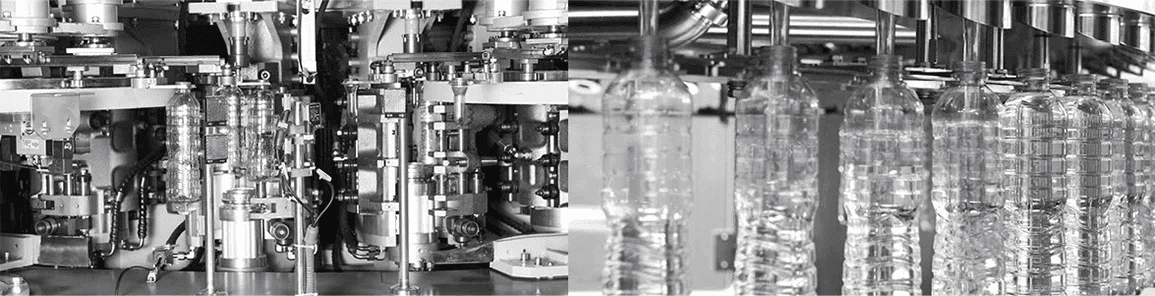

The Extrusion Blow Molding Machine is an advanced device that can create high-quality plastic products in a shorter amount of time. It is a fully automated process, and the machine is equipped with sensors that can monitor the entire process.

The machine is composed of four main parts: the extruder, the die head, the blow molding unit, and the control system. These parts work together in creating bottles, containers, and other items made of plastic.

Advantages of Extrusion Blow Molding

There are many advantages that come with using the Extrusion Blow Molding Machine. Here are some of them:

1. High-volume production: The Extrusion Blow Molding Machine can produce a large number of plastic products in less time.

2. Low labor costs: The process is fully automated, reducing the need for manual labor.

3. Versatility: The machine can produce a variety of plastic products, including bottles, containers, and toys.

4. Low material waste: The machine can precisely control the amount of plastic material used in creating the product, reducing the amount of waste produced.

Conclusion

The Extrusion Blow Molding Machine has revolutionized the blow molding manufacturing process, making it faster, more efficient, and more automated than ever before. It has become a cornerstone in the plastic manufacturing industry, producing high-quality plastic products in large quantities while keeping costs low.

Now that you have a better understanding of blow molding and the importance of Extrusion Blow Molding Machine, you can start exploring its potential in the world of plastic manufacturing.