Soldering is a process of joining two or more metal pieces together by melting and flowing a filler metal, called solder, into the joint. It is a widely used technique in industries like electronics, plumbing, and jewelry-making. The process is simple and affordable, but requires skill and precision to ensure a strong, reliable bond.

For decades, soldering has been a staple in the electronics industry, particularly in the manufacture of printed circuit boards (PCBs). PCBs are used in almost all electronic devices and consist of a thin board made of non-conducting material, like fiberglass or plastic, on which tiny electronic components are mounted. To connect these components, solder is used to create electrical connections between them and the board.

The importance of soldering in the electronics industry cannot be overstated. Without the proper application of solder, electronic devices may not function properly, and could even be dangerous. For example, a poorly soldered circuit in a medical device could fail during surgery, putting the patient's life in danger.

Soldering is also used in the plumbing industry. It is a way to join two pipes together without the need for expensive welding equipment. The process involves heating the joint until it gets hot enough to melt the solder, which then flows into the gap between the two pipes, forming a strong bond.

In jewelry-making, soldering is used to attach small metal parts together, such as clasps and jump rings. It is also used to create complex designs, by soldering metal pieces of different shapes and sizes together.

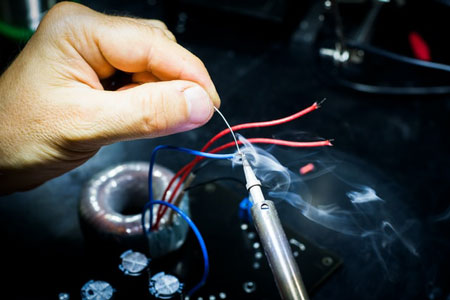

The process of soldering requires skill and patience. It involves precise handling of the soldering iron, the filler metal, and the parts being joined together. The soldering iron needs to be heated to the correct temperature, and the solder needs to be prepared and applied in the correct amount.

The filler metal used in soldering is usually an alloy, which means it consists of two or more metals. The most commonly used solder alloys are tin-lead and lead-free solder. Tin-lead solder was widely used in the past but has health concerns due to its lead content. Lead-free solder has become the preferred choice in recent years, as it is environmentally friendly and safer for workers.

In conclusion, soldering is a vital process in industries that rely on strong, reliable bonds between metal parts. It is simple, affordable, and versatile, and can be used in a variety of applications. However, it requires skill and precision to ensure a proper bond. With proper training and practice, anyone can become proficient in the art of soldering.