Products Details

| GB | / |

| UNS | C17200 |

| EN | CW101C/CuBe2 |

| JIS | / |

| Copper, Cu | Rem. |

| Beryllium, Be | 1.80 – 2.00% |

| Cobalt, Co | Min. 0.20% |

| Co+Ni+Fe | Min. 0.60% |

| Density | 8.36 g/cm3 |

| Electrical Conductivity | Min. 22 %IACS |

| Thermal Conductivity | 107 W/( m·K) |

| Coefficiency of Thermal Expansion | 17.5 μm/(m·K) |

| Specific Heat Capacity | 419 J/(kg·K) |

| Modulus of Elasticity | 131 Gpa |

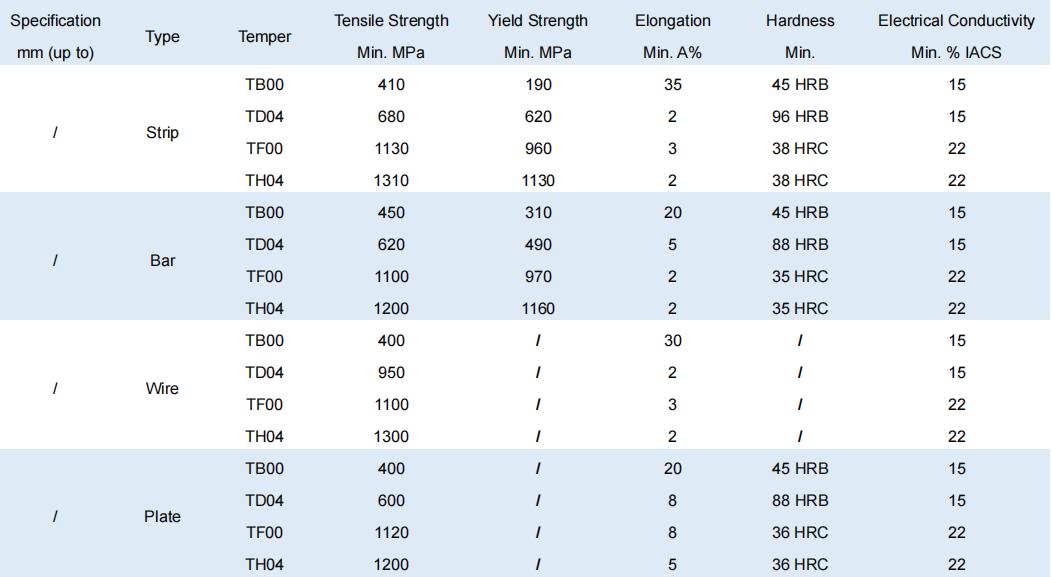

CAMK17200 is the most commonly specified copper beryllium. In its age hardened condition, it attains the highest strength and hardness of any commercial copper base alloy. The ultimate tensile strength can exceed 1360Mpa(200 ksi), while the hardness approaches Rockwell C45. Also, in the fully aged condition, the electrical conductivity is a minimum of 22% IACS (International Annealed Copper Standard). It also exhibits exceptional resistance to stress relaxation at elevated temperatures.1. Electrical Industry: Electrical Switch and Relay Blades, Fuse Clips, Switch Parts, Relay parts, Connectors, Spring Connectors, Contact Bridges, Belleville Washers, etc. 2. Fasteners: Washers, Fasteners, Lock Washers, Retaining Rings, Roll Pins, Screws, Bolts. 3. Industrial: Pumps, Springs, Electrochemical, Shafts, Non Sparking Safety Tools, Flexible Metal Hose, Housings for Instruments, Bearings, Bushings, Valve Seats, etc.

Car Dashboard Accessories,

Bismuth Copper Alloy,

Black Master Batch,

Angle Die Grinder,

Copper Tellurium,

Beryllium copper alloy products,

Electronic products,

Petg Plastic,

Roofing Nailer,

In Molding,